Optimize your journey

Accelerate and simplify your path to cost-competitive, safe, and reliable green hydrogen Power-to-X production.

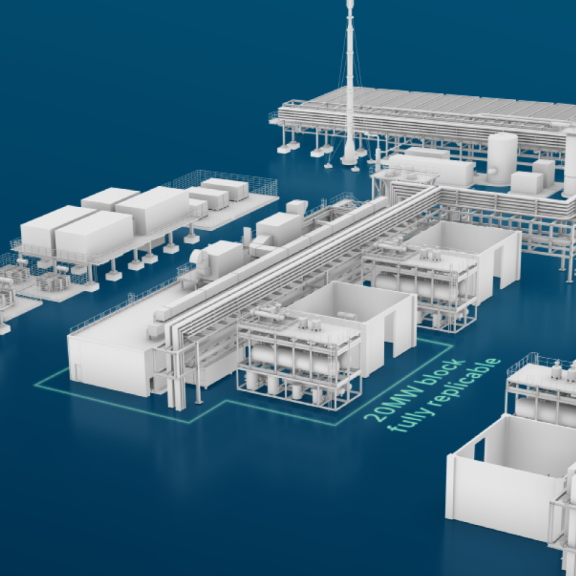

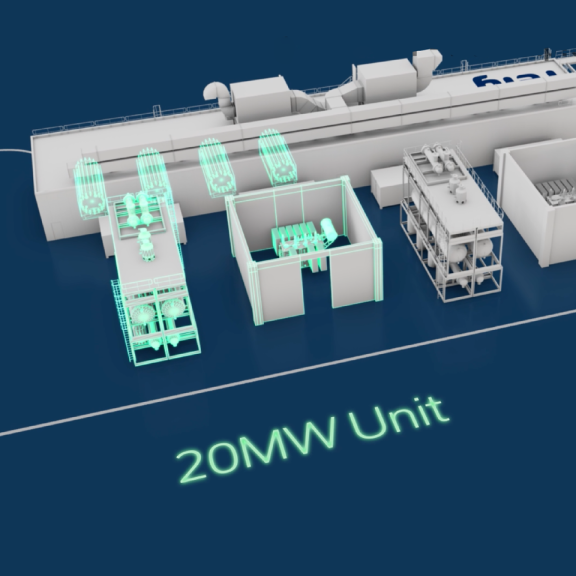

With a standardized yet configurable and scalable design, full automation, performance guarantees, and shorter lead time, Rely Clear100+ ensures lower LCOH, less project risk, and faster ROI.

Clear100⁺ is not just a product—it’s a platform. One that’s designed to scale, adapt, and evolve with our client's energy transition journey.

Innovation is not just about new tech—it’s about solving real-world problems. With Clear100+, we’ve embedded continuous improvement into our DNA. Every iteration / generation is informed by operational feedback, evolving regulations, and market needs. This ensures our clients stay ahead—technically, economically, and environmentally

Safety

Within the challenging and highly competitive global energy industry, Rely excels by making Quality, Health, Safety, Environment and Security (QHSES) our top priorities. We're committed to looking after our teams and safeguarding our projects while delivering to the very highest standards. Clear100⁺ onboards all HSE standards and has been designed with a safety-by-design rigorness.

As a company committed to decarbonization solutions, we aim to develop end-to-end solutions that cover all the other components of the environment.

Power-to-X

Clear100+ is your first step in optimizing Power-to-X production. Since green hydrogen can represent up to 60% of the total cost of derivatives, efficient management is crucial. Rely delivers seamless integration of technologies from leading partners to support all your Power-to-X needs.

Operations & Maintenance (O&M)

As a true one-stop shop, Rely supports your green hydrogen journey end-to-end – from installation to long-term performance. We provide performance guarantees and integrated solutions to ensure smoother O&M for your Clear100+plant. Partnering with Rely also gives your plant early access to innovative new products like the iEMS, designed to further enhance operational efficiency.